Insert bearing, also known as a "insert ball bearing," is a type of bearing that is designed to fit into a housing. These bearings typically consist of an outer ring, an inner ring, and a set of balls that are positioned between the two rings. The outer ring of an insert bearing typically has a spherical or cylindrical shape, while the inner ring is usually designed to fit onto a shaft.

Insert bearings are commonly used in applications where the bearing needs to be easily mounted and dismounted, such as in agricultural equipment, conveyor systems, and packaging machinery. They can also be used in applications where there are high levels of contamination, as the bearings are often designed with seals or shields to protect the rolling elements from dirt and debris.

The insert bearing is a type of bearing that is designed to fit inside a housing unit, such as a pillow block or flange unit. It is commonly used in machinery and equipment to support rotating shafts and reduce friction between moving parts.

The insert bearing structure typically consists of three main components: the inner ring, the outer ring, and the rolling elements. The inner ring is mounted on the shaft and rotates with it, while the outer ring is fixed to the housing unit. The balls are located between the inner and outer rings and enable smooth rotation.

The inner ring of the insert bearing is usually equipped with a locking mechanism to securely fasten the bearing to the shaft. This can be achieved through different means, such as setscrews, eccentric locking collars, or adapter sleeves.

The outer ring of the insert bearing is often designed with a spherical shape to allow for some misalignment between the shaft and the housing unit. This can help to compensate for any slight variations in alignment or deflection that may occur during operation.

Insert bearings are available in different materials, sizes, and configurations to meet various application requirements. Common materials include steel, stainless steel, and plastic. The size of the insert bearing is determined by its bore diameter, which should match the diameter of the shaft.

Insert bearings are designed to have some features that make them well-suited for use in machinery and equipment applications. Here are some of the key features of insert bearings:

1. Versatile mounting options: Insert bearings can be mounted in a variety of ways, such as by using setscrews, eccentric locking collars, or adapter sleeves. This makes them easy to install and allows for some flexibility in terms of how they are attached to the shaft.

2. Spherical outer ring: The outer ring of an insert bearing is typically designed with a spherical shape. This allows for some misalignment between the shaft and the housing unit, which can help to reduce stress and wear on the bearing.

3. Lubrication options: Insert bearings can be lubricated in a variety of ways, such as with grease or oil. Some bearings may also have seals or shields to help protect against contamination and retain the lubricant.

4. Corrosion resistance: Insert bearings are often made from materials that are resistant to corrosion, such as stainless steel. This can be important in applications where the bearing may be exposed to moisture or other corrosive substances.

5. High load capacity: Insert bearings are designed to handle high radial and axial loads, making them well-suited for use in heavy-duty machinery and equipment applications.

We produce insert bearing mainly through the following steps:

1. Material selection: The first step in producing insert bearings is to select the appropriate materials. This can include choosing the right type of steel for the bearing components and selecting the proper lubricant for the application.

2. Machining: Once the materials have been selected, the bearing components are machined to the correct specifications. This can involve turning, milling, drilling, and grinding the components to the required tolerances.

3. Heat treatment: After the components have been machined, they are heat-treated to increase their strength and durability. This can involve processes such as quenching and tempering or case hardening.

4. Finishing: Once the insert bearings have been heat-treated, they may undergo additional finishing processes to smooth out any rough edges or surface imperfections. This may involve grinding, polishing, or other methods of surface treatment.

5. Assembly: The individual components of the insert bearing are then assembled together. This can involve press-fitting the inner and outer races onto the bearing housing, installing the balls or rollers, and adding the seals and shields.

6. Lubrication: Before the bearing is packaged and shipped, it is lubricated with the appropriate grease or oil for the application.

7. Quality control: Throughout the production process, quality control measures are in place to ensure that the bearings meet the required specifications. This can involve inspections and testing of the individual components as well as the finished bearings.

8. Packaging and shipping: The insert bearing that has undergone quality inspection need to be packaged to protect them from damage. Common packaging materials include cartons, wooden boxes, and pallets. Finally, the products can be shipped to customers by sea, air, or land transportation.

JET Insert Bearings have two categories: Metric and Inch

JET Insert Bearings includes requiring maintenance (steel–on-steel) & maintenance-free.

Bore diameter is 4-200mm for metric dimensions, 0.19-4.75 inch for inch dimensions.

Different sliding contact surface combinations with inner rings and out rings can be made of different materials.

The structure is divided into two kinds: standard type and overloading, in addition, the inner ring with spherical, hemispherical and steps.

UC series: UC201, UC202, UC203, UC204, UC205, UC206, UC207, UC208, UC209, UC210, UC211, UC212, UC213,UC214, UC215, UC216, UC217, UC218,UC219,UC220

UC305, UC306, UC307, UC308, UC309, UC310, UC311, UC312, UC313, UC314, UC315, UC316, UC317, UC318, UC319,UC320

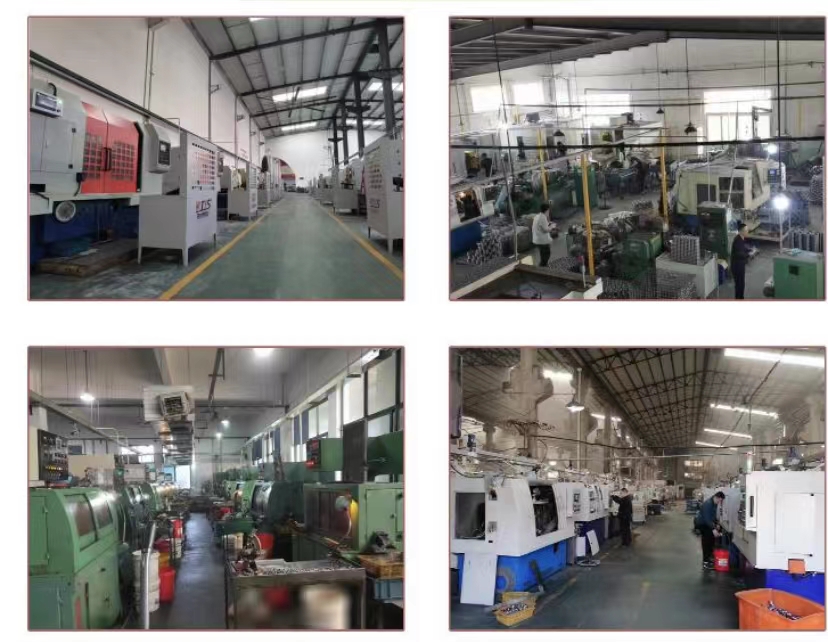

Our Production Workshop

Why choose us

(1) Advanced production equipment

(2) Strong technical force

(3) High production capacity

(4) Short delivery time

(5) Low MOQ

(6) Strict quality control

(7) Competitive price

(8) ISO9001:2018 passed

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer.We have our own factory ;our type is factory +trade

Q2: How long is your delivery time?

A2: Generally it is 15-20 days, if the goods are in stock, it is 3-7 days, if the goods are not in stock, it depends on the quantity.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples for free, but we don't pay shipping fee.

Q4. How do you control the quality,and what if there is quality problem?

A4: All bearings will be 100% strictly inspected before shipment, including hardness, size, noise, speed, vibration and accuracy. If there is any quality problem, we will replace all faulty products with our shipping cost or refund to you.

Q5:OEM and customized can you accept?

A5: Yes, OEM is accepted, also can be customized for you according to samples or drawings

Q6: What are your shipping conditions.

A6: We can arrange shipping by sea to your nearest seaport or deliver to your doorstep. Air freight is also possible. We can help with all import formalities. It takes about 25-40 days by sea and 3-7 days by air.

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park,Xishan District, Wuxi City, Jiangsu Province, China

Contact: Zhang lianjie

Тел.: +86 13771539960

Почта: jason@jetbearing.com

Whatsapp:+86 13771539960

Адрес компании: №25, Промышленный парк Гуантай, район Сишань, город Уси, провинция Цзянсу, Китай

We chat