Double direction thrust ball bearing is a special type of thrust bearing that can withstand thrust loads from two directions. It is typically composed of an inner ring, an outer ring, a set of steel balls, and a retainer. The steel balls rotate between the inner and outer rings, allowing the bearing to support both axial and radial loads.

Unlike a single direction thrust ball bearing, a double-direction thrust ball bearing has two adjustable contact angles, which determine the bearing's load-bearing capacity and operating characteristics. This makes double-direction thrust ball bearings more suitable for bearing bidirectional thrust loads than single-direction thrust ball bearings.

The construction of a double-direction thrust ball bearing mainly consists of balls, a retainer, two seat rings, and two washers. Below is a detailed introduction to each part:

Inner Ring: The inner ring is the internal part of the bearing and is usually fixed on the shaft. The surface of the inner ring is usually designed with a raceway to allow the steel balls to rotate on its surface.

Outer Ring: The outer ring is the external part of the bearing and is usually mounted in the bearing housing. The surface of the outer ring is also usually designed with a raceway to allow the steel balls to rotate on its surface.

Steel Balls: The core part of a double-direction thrust ball bearing is the steel balls. The steel balls are typically made of high-strength steel and are placed between the inner and outer rings to withstand thrust loads.

Retainer: The main function of the retainer is to arrange the balls in a dispersed manner and maintain their spacing. The retainer is usually made of materials such as copper, steel, or plastic.

We produce double direction thrust ball bearing have the following characteristics:

1. Ability to withstand bidirectional thrust loads: Double-direction thrust ball bearings can withstand thrust loads from both directions, which can effectively support mechanical equipment under bidirectional thrust loads.

2. Strong load-carrying capacity: Due to the use of spherical rolling elements, double-direction thrust ball bearings have a high load-carrying capacity and can withstand large axial and radial loads.

3. High precision: Double-direction thrust ball bearings have high precision and stability, which can ensure smooth operation and accuracy of mechanical equipment.

4. Easy installation: Double-direction thrust ball bearings have a relatively simple structure, and the installation process is relatively simple, without the need for complex tools and techniques.

5. Long service life: The excellent design and material quality of double-direction thrust ball bearings result in a relatively long service life, making them suitable for long-term use in mechanical equipment.

We produce double direction thrust ball bearing mainly through the following steps:

1. Material preparation: The manufacturing materials of the bi-directional thrust ball bearing are usually high-quality steel or ceramics. Prior to production, the raw materials need to be selected, processed, and cleaned to ensure their quality and performance.

2. Ball production: The ball is an important component of the bi-directional thrust ball bearing, and its production requires multiple steps, including cold heading, heat treatment, grinding, polishing, etc. These processes can ensure the size accuracy and surface quality of the ball, as well as improve its strength and hardness.

3. Cage production: The cage of the bi-directional thrust ball bearing is usually made of copper, steel, or plastic. The production of the cage needs to be completed through mold forming, processing, and surface treatment steps.

4. Raceway production: The raceway is another important component of the bi-directional thrust ball bearing, and its production requires multiple steps, including forging, turning, heat treatment, grinding, polishing, etc. These processes can ensure the size accuracy and surface quality of the raceway, as well as improve its strength and hardness.

5. Washer production: The washer is usually made of materials such as steel or copper, and its production needs to be completed through mold forming, processing, and surface treatment steps.

6. Assembly: During the assembly process of the bi-directional thrust ball bearing, the ball, cage, raceway, washer, and other components need to be assembled to ensure that each bearing meets the requirements.

7. Inspection: The assembled bearings need to undergo various inspections, including visual inspection, precision inspection, and load capacity inspection. Only after passing the inspection can the bearings be considered qualified products.

8. Packaging and shipment: The inspected bi-directional thrust ball bearings need to be packaged and accompanied by corresponding quality certification documents before being shipped to customers.

Series:52200Series,52300Series,52400Series,54200Series,54300Series,54400Series

Material:Chrome steel (Gcr15)

Cages:steel cages, brass cages

Quality: ABEC-1(P0)、ABEC-3(P6)、ABEC-5(P5)

Noise Level: Z1V1,Z2V2,Z3V3,Z4V4

Application:Agriculture, cement industry, crusher industry, heavy machinery and equipment, household appliances, textile industry, electricity, steel, metallurgy, machine tools, automobiles, precision instruments, mining machinery, construction machinery, railways, etc.

Package

A. Industrial Exporting Package with anti-tarnish

paper/Carton/Pallet

B. Individual Paper Box/Carton/Pallet

C: tube package+middle box+outer carton+pallets

D: According to your requirement.

Double Direction Thrust Ball Bearing Product List

| Bearing Model | Dimensions(mm) | Basic Load Rating(N) | Limitting Speeds (r.min) | Weight (Kg) | ||||

| d | D | B | Dyn.c | Stat.Co | Grease | Oil | ||

| 52205 | 25 | 47 | 28 | 27.7 | 50.4 | 3600 | 5500 | 0.23 |

| 52206 | 30 | 52 | 29 | 28.1 | 54.3 | 3400 | 5200 | 0.27 |

| 52207 | 35 | 62 | 34 | 40.7 | 83.8 | 2900 | 4500 | 0.42 |

| 52208 | 40 | 68 | 36 | 46.9 | 98.3 | 2700 | 4200 | 0.54 |

| 52209 | 45 | 73 | 37 | 47.7 | 105 | 2600 | 4000 | 0.64 |

| 52210 | 50 | 78 | 39 | 48.5 | 111 | 2300 | 3600 | 0.71 |

| 52211 | 55 | 90 | 45 | 69.4 | 159 | 2100 | 3200 | 1.12 |

| 52212 | 60 | 95 | 46 | 73.6 | 179 | 1900 | 3000 | 1.15 |

| 52213 | 65 | 100 | 47 | 74.8 | 189 | 1900 | 2900 | 1.36 |

| 52214 | 70 | 105 | 47 | 73.6 | 189 | 1800 | 2800 | 1.52 |

| 52215 | 75 | 110 | 47 | 77.4 | 209 | 1800 | 2700 | 1.6 |

| 52307 | 35 | 68 | 44 | 55.5 | 105 | 2400 | 3700 | 0.71 |

| 52308 | 40 | 78 | 49 | 69.3 | 135 | 2100 | 3300 | 1.06 |

| 52309 | 45 | 85 | 32 | 80 | 163 | 1900 | 3000 | 1.26 |

| 52310 | 50 | 95 | 58 | 91.6 | 186 | 1800 | 2700 | 1.68 |

| 52311 | 55 | 105 | 64 | 119 | 246 | 1600 | 2400 | 2.5 |

| 52312 | 60 | 110 | 64 | 124 | 267 | 1500 | 2300 | 2.7 |

| 52313 | 65 | 115 | 65 | 128 | 287 | 1400 | 2200 | 2.9 |

| 52314 | 70 | 125 | 72 | 148 | 339 | 1300 | 2000 | 3.9 |

| 52315 | 75 | 135 | 79 | 171 | 396 | 1200 | 1900 | 5 |

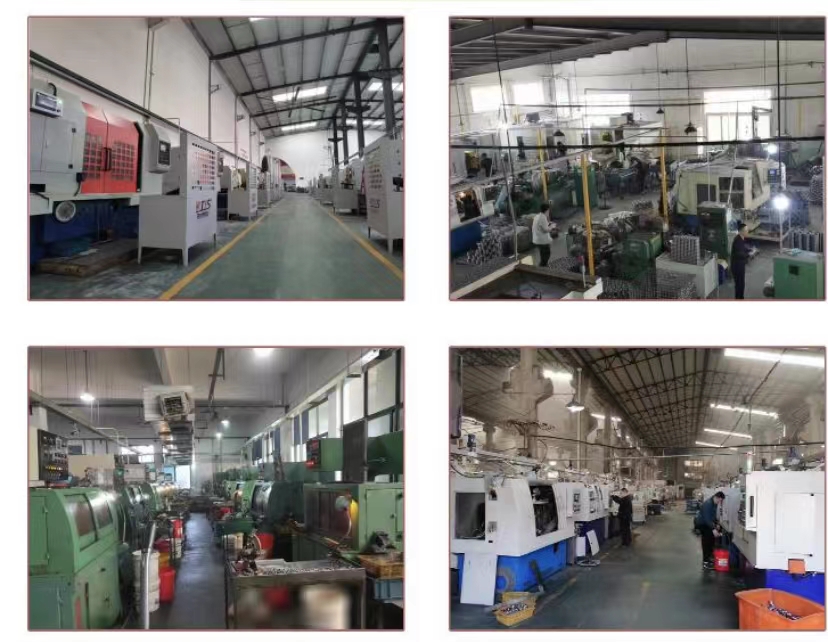

Our Production Workshop

Why choose us

(1) Advanced production equipment

(2) Strong technical force

(3) High production capacity

(4) Short delivery time

(5) Low MOQ

(6) Strict quality control

(7) Competitive price

(8) ISO9001:2018 passed

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer.We have our own factory ;our type is factory +trade

Q2: How long is your delivery time?

A2: Generally it is 15-20 days, if the goods are in stock, it is 3-7 days, if the goods are not in stock, it depends on the quantity.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples for free, but we don't pay shipping fee.

Q4. How do you control the quality,and what if there is quality problem?

A4: All bearings will be 100% strictly inspected before shipment, including hardness, size, noise, speed, vibration and accuracy. If there is any quality problem, we will replace all faulty products with our shipping cost or refund to you.

Q5:OEM and customized can you accept?

A5: Yes, OEM is accepted, also can be customized for you according to samples or drawings

Q6: What are your shipping conditions.

A6: We can arrange shipping by sea to your nearest seaport or deliver to your doorstep. Air freight is also possible. We can help with all import formalities. It takes about 25-40 days by sea and 3-7 days by air.

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park, Xishan District, Wuxi City, Jiangsu Province, China

Contact: Zhang lianjie

Тел.: +86 13771539960

Почта: jason@jetbearing.com

Whatsapp:+86 13771539960

Адрес компании: №25, Промышленный парк Гуантай, район Сишань, город Уси, провинция Цзянсу, Китай

We chat