Angular contact ball bearings are a type of high-precision rolling bearing composed of an inner ring, an outer ring, a cage, and steel balls. The inner and outer rings of angular contact ball bearings are both arc-shaped, and their geometric centers do not coincide, giving the bearing the characteristic of contact angle. The steel balls are placed between the inner and outer rings and are arranged equidistantly through the cage. When subjected to loads, the steel balls can roll freely, allowing the bearing to withstand loads and moments in multiple directions. Additionally, the free rolling of the steel balls results in relatively low friction and noise.

The seals of angular contact ball bearings can prevent dust and water, maintain lubricating oil inside the bearing, and prevent external impurities from entering. This can prolong the service life of the bearing and improve its performance.

Angular contact ball bearings are a type of bearing that can withstand axial and radial loads, and their structure is as follows:

Inner and outer rings: The inner and outer rings of angular contact ball bearings are both rolling tracks. The inner ring is mounted on the shaft, and the outer ring is mounted in the bearing housing.

Balls: The rolling elements of angular contact ball bearings are spherical balls, which can withstand radial and axial loads.

Cage: The cage is used to maintain the spacing and relative positions of the balls. Common cage materials include steel, copper, nylon, and so on.

We produce angular contact ball bearing have the following characteristics:

1. Can withstand radial and axial loads: The inner and outer rings, as well as the rolling elements of angular contact ball bearings, are all spherical, which can withstand radial and axial loads, making them suitable for high-speed, high-load, and high-precision working conditions.

2. High speed: Due to the contact points of its rolling elements being at a certain angle, it can maintain stability during high-speed rotation, making it suitable for high-speed rotating machinery.

3. Large contact angle: The contact angle of angular contact ball bearings is generally 15 degrees, 25 degrees, or 40 degrees. Compared with deep groove ball bearings, the contact angle is larger, making it capable of bearing larger axial loads.

4. High precision: Angular contact ball bearings require high machining accuracy, thus obtaining higher positioning and rotation accuracy, making them suitable for precision machinery.

5. Adjustable angle: The contact angle between the inner and outer rings of angular contact ball bearings can be adjusted, and different contact angles can be designed to meet the needs of different working conditions.

6. Good sealing performance: Angular contact ball bearings can be equipped with sealing pads to prevent dust and debris from entering the bearing, maintaining stability and prolonging the bearing's life.

7.Even load distribution: The contact points of angular contact ball bearings are distributed at both ends of the rolling elements, resulting in an even load distribution, reducing the wear and damage of the bearings.

We produce angular contact ball bearing mainly through the following steps:

1. Raw material preparation: The manufacture of angular contact ball bearings requires the selection of high-quality bearing steel materials, typically GCr15. These raw materials need to undergo strict chemical composition analysis and mechanical property testing to ensure that the quality and performance of the materials meet the requirements.

2. Heat treatment: Through forging, quenching, tempering, and other heat treatment processes, the bearing steel material is given excellent mechanical properties and wear resistance. This is one of the critical steps in bearing production.

3. Cold drawing and tube making: Using the cold drawing and tube making process, the heat-treated bearing steel material is made into steel pipes with diameters and wall thicknesses that meet the requirements. This step requires precise control of the accuracy and surface quality of the tubes.

4. Bar turning: The bearing steel material made into steel pipes is cut into appropriate lengths of cylinders, then rough ground and precision ground, and finally turned into cylinders with diameters slightly larger than the required inner and outer rings. This step requires precise control of dimensions such as roundness and straightness.

5. Ball processing: The bearing steel material is made into balls with diameters that meet the requirements, generally using processes such as cold extrusion of steel balls, steel ball grinding, and steel ball hot pressing. This step requires precise control of sphericity and surface quality.

6. Precision machining: Using precision machining equipment such as CNC machine tools and grinders, the inner and outer rings and balls are precisely machined to ensure the geometric accuracy and surface quality of the angular contact ball bearings. This step includes precision grinding of the inner and outer rings, ball and inner/outer raceway matching, and control of the clearance fit.

7. Assembly: The inner and outer rings and balls are assembled together, and the retaining cage and sealing device are installed to form a complete angular contact ball bearing. This step requires strict control of assembly quality and clearance to ensure bearing performance.

8. Inspection: Multiple inspections are performed on the produced angular contact ball bearings, including visual inspection, dimension measurement, and hardness testing, to ensure product quality. Only products that meet the inspection requirements can proceed to the next step of sales and use.

9. Packaging and shipping: The angular contact ball bearings that have undergone quality inspection need to be packaged to protect them from damage. Common packaging materials include cartons, wooden boxes, and pallets. Finally, the products can be shipped to customers by sea, air, or land transportation.

Series: 7000Series ,7200Series,7300Series,7400Series

Cages:steel cages, brass cages , nylon cage

Quality: ABEC-1(P0)、ABEC-3(P6)、ABEC-5(P5)ABEC-7(P4)

Noise Level: Z1V1, Z2V2, Z3V3, Z4V4

Material:Chrome Steel GCr15

Application: Machine Tool Spindles, Gearboxes, Gearboxes Automotive, Metal Industry, Textile Industry, Aerospace Applications, Pumps and Motors, Railway Applications

Package

A. Industrial Exporting Package with anti-tarnish

paper/Carton/Pallet

B. Individual Paper Box/Carton/Pallet

C: tube package+middle box+outer carton+pallets

D: According to your requirement.

Angular Contact Ball Bearings Product List

| Bearing Model | Dimensions(mm) | Basic Load Rating(N) | Limiting Speed(r/min) | Weight(KG) | ||||

| d | D | b | Dyn.C | Stat.CO | Grease | Oil | ||

| 7000 | 10 | 26 | 8 | 5300 | 2450 | 47000 | 62000 | 0.025 |

| 7001 | 12 | 28 | 8 | 5800 | 2950 | 40000 | 54000 | 0.027 |

| 7002 | 15 | 32 | 9 | 6600 | 3700 | 35000 | 47000 | 0.039 |

| 7003 | 17 | 35 | 10 | 7300 | 4450 | 31000 | 41000 | 0.051 |

| 7004 | 20 | 42 | 12 | 11100 | 6600 | 26000 | 35000 | 0.089 |

| 7005 | 25 | 47 | 12 | 12300 | 8000 | 23000 | 30000 | 0.103 |

| 7006 | 30 | 55 | 13 | 15800 | 11000 | 20000 | 26000 | 0.15 |

| 7007 | 35 | 62 | 14 | 19100 | 13700 | 17000 | 22000 | 0.207 |

| 7008 | 40 | 68 | 15 | 20500 | 15900 | 15000 | 20000 | 0.247 |

| 7009 | 45 | 75 | 16 | 24400 | 19300 | 14000 | 18000 | 0.31 |

| 7010 | 50 | 80 | 16 | 26000 | 21900 | 13000 | 17000 | 0.35 |

| 7011 | 55 | 90 | 18 | 34100 | 28600 | 11000 | 15000 | 0.47 |

| 7012 | 60 | 95 | 18 | 35000 | 30600 | 11000 | 14000 | 0.5 |

| 7013 | 65 | 100 | 18 | 37100 | 34300 | 10000 | 13000 | 0.54 |

| 7014 | 70 | 110 | 20 | 46900 | 43000 | 9200 | 12000 | 0.81 |

| 7015 | 75 | 115 | 20 | 48000 | 45600 | 8700 | 11000 | 0.86 |

| 7016 | 80 | 125 | 22 | 58700 | 55300 | 8000 | 11000 | 1.11 |

| 7017 | 85 | 130 | 22 | 60100 | 58700 | 7600 | 10000 | 1.25 |

| 7018 | 90 | 140 | 24 | 71700 | 69100 | 7100 | 9400 | 1.58 |

| 7020 | 100 | 150 | 24 | 75300 | 77200 | 6500 | 8600 | 1.72 |

| 7200 | 10 | 30 | 9 | 5000 | 2350 | 40000 | 54000 | 0.032 |

| 7201 | 12 | 32 | 10 | 7900 | 3850 | 38000 | 50000 | 0.039 |

| 7202 | 15 | 35 | 11 | 8650 | 4550 | 33000 | 43000 | 0.048 |

| 7203 | 17 | 40 | 12 | 10900 | 5900 | 29000 | 38000 | 0.069 |

| 7204 | 20 | 47 | 14 | 15500 | 9000 | 24000 | 32000 | 0.11 |

| 7205 | 25 | 52 | 15 | 16600 | 10200 | 21000 | 28000 | 0.13 |

| 7206 | 30 | 62 | 16 | 23000 | 14700 | 18000 | 24000 | 0.217 |

| 7207 | 35 | 72 | 17 | 25600 | 17000 | 8300 | 11000 | 0.313 |

| 7208 | 40 | 80 | 18 | 36400 | 25200 | 14000 | 18000 | 0.402 |

| 7209 | 45 | 85 | 19 | 40800 | 28700 | 13000 | 17000 | 0.46 |

| 7210 | 50 | 90 | 20 | 42800 | 31800 | 12000 | 16000 | 0.51 |

| 7211 | 55 | 100 | 21 | 52900 | 40200 | 11000 | 14000 | 0.68 |

| 7212 | 60 | 110 | 22 | 64000 | 49500 | 9500 | 13000 | 1.02 |

| 7213 | 65 | 120 | 23 | 73100 | 58700 | 8900 | 12000 | 1.09 |

| 7214 | 70 | 125 | 24 | 75900 | 60200 | 8400 | 11000 | 1.18 |

| 7215 | 75 | 130 | 25 | 86100 | 70600 | 8000 | 11000 | 1.32 |

| 7216 | 80 | 140 | 26 | 92800 | 77500 | 7500 | 9900 | 1.57 |

| 7218 | 90 | 160 | 30 | 123000 | 105000 | 6500 | 8600 | 2.47 |

| 7219 | 95 | 170 | 32 | 133000 | 112000 | 6100 | 8100 | 3.02 |

| 7220 | 100 | 180 | 34 | 149000 | 127000 | 5700 | 7600 | 3.62 |

| 7300 | 10 | 35 | 11 | 9850 | 4600 | 36000 | 49000 | 0.054 |

| 7301 | 12 | 37 | 12 | 10800 | 4900 | 33000 | 45000 | 0.065 |

| 7302 | 15 | 42 | 13 | 13300 | 6850 | 28000 | 39000 | 0.088 |

| 7303 | 17 | 47 | 14 | 15800 | 8400 | 25000 | 33000 | 0.121 |

| 7304 | 20 | 52 | 15 | 18500 | 9950 | 23000 | 31000 | 0.156 |

| 7305 | 25 | 62 | 17 | 26400 | 15300 | 19000 | 25000 | 0.248 |

| 7306 | 30 | 72 | 19 | 32300 | 20300 | 16000 | 21000 | 0.381 |

| 7307 | 35 | 80 | 21 | 37900 | 23600 | 14000 | 19000 | 0.512 |

| 7309 | 45 | 100 | 25 | 59200 | 39700 | 11000 | 15000 | 0.97 |

| 7310 | 50 | 110 | 27 | 75100 | 51600 | 10000 | 13000 | 1.23 |

| 7311 | 55 | 120 | 29 | 86800 | 60600 | 9300 | 12000 | 1.57 |

| 7312 | 60 | 130 | 31 | 99200 | 70300 | 8600 | 11000 | 1.696 |

| 7313 | 65 | 140 | 33 | 112000 | 80700 | 8000 | 11000 | 2.38 |

| 7314 | 70 | 150 | 36 | 126000 | 91900 | 7500 | 9900 | 2.89 |

| 7315 | 75 | 160 | 37 | 137000 | 104000 | 7000 | 9200 | 3.47 |

| 7316 | 80 | 170 | 39 | 149000 | 117000 | 6500 | 4600 | 4.13 |

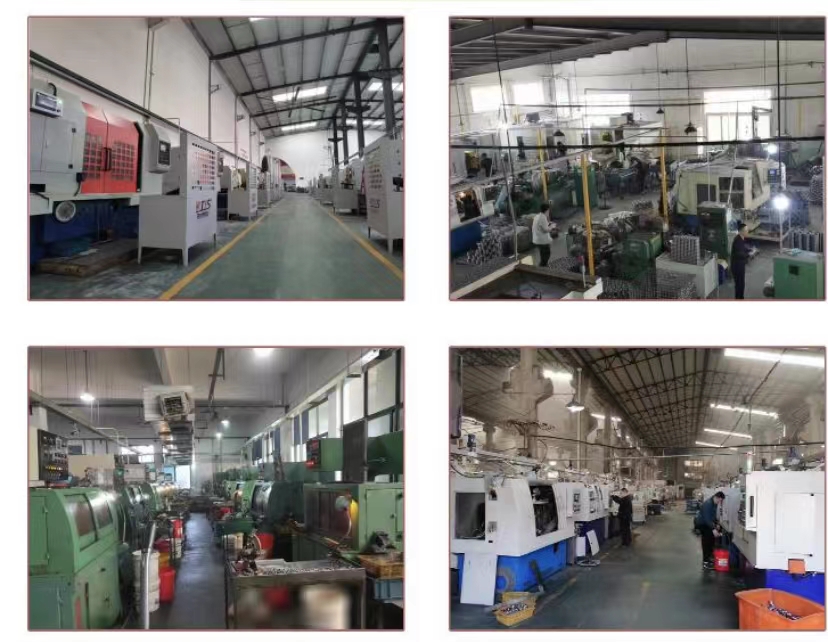

Our Production Workshop

Why choose us

(1) Advanced production equipment

(2) Strong technical force

(3) High production capacity

(4) Short delivery time

(5) Low MOQ

(6) Strict quality control

(7) Competitive price

(8) ISO9001:2018 passed

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer.We have our own factory ;our type is factory +trade

Q2: How long is your delivery time?

A2: Generally it is 15-20 days, if the goods are in stock, it is 3-7 days, if the goods are not in stock, it depends on the quantity.

Q3: Do you provide samples? Is it free or extra?

A3: Yes, we can provide samples for free, but we don't pay shipping fee.

Q4. How do you control the quality,and what if there is quality problem?

A4: All bearings will be 100% strictly inspected before shipment, including hardness, size, noise, speed, vibration and accuracy. If there is any quality problem, we will replace all faulty products with our shipping cost or refund to you.

Q5:OEM and customized can you accept?

A5: Yes, OEM is accepted, also can be customized for you according to samples or drawings

Q6: What are your shipping conditions.

A6: We can arrange shipping by sea to your nearest seaport or deliver to your doorstep. Air freight is also possible. We can help with all import formalities. It takes about 25-40 days by sea and 3-7 days by air.

Contact: Zhang lianjie

Phone: +86 13771539960

E-mail: jason@jetbearing.com

Whatsapp:+86 13771539960

Add: No.25, Guangtai Industry Park, Xishan District, Wuxi City, Jiangsu Province, China

Contact: Zhang lianjie

Тел.: +86 13771539960

Почта: jason@jetbearing.com

Whatsapp:+86 13771539960

Адрес компании: №25, Промышленный парк Гуантай, район Сишань, город Уси, провинция Цзянсу, Китай

We chat